How to Maintain and Clean Your Model Trains

Keeping model trains in top condition is a crucial part of enjoying the hobby. Model railroading enthusiasts know that a well-maintained train runs smoother and lasts longer. To ensure your model trains stay in excellent shape, regular cleaning and proper maintenance are essential.

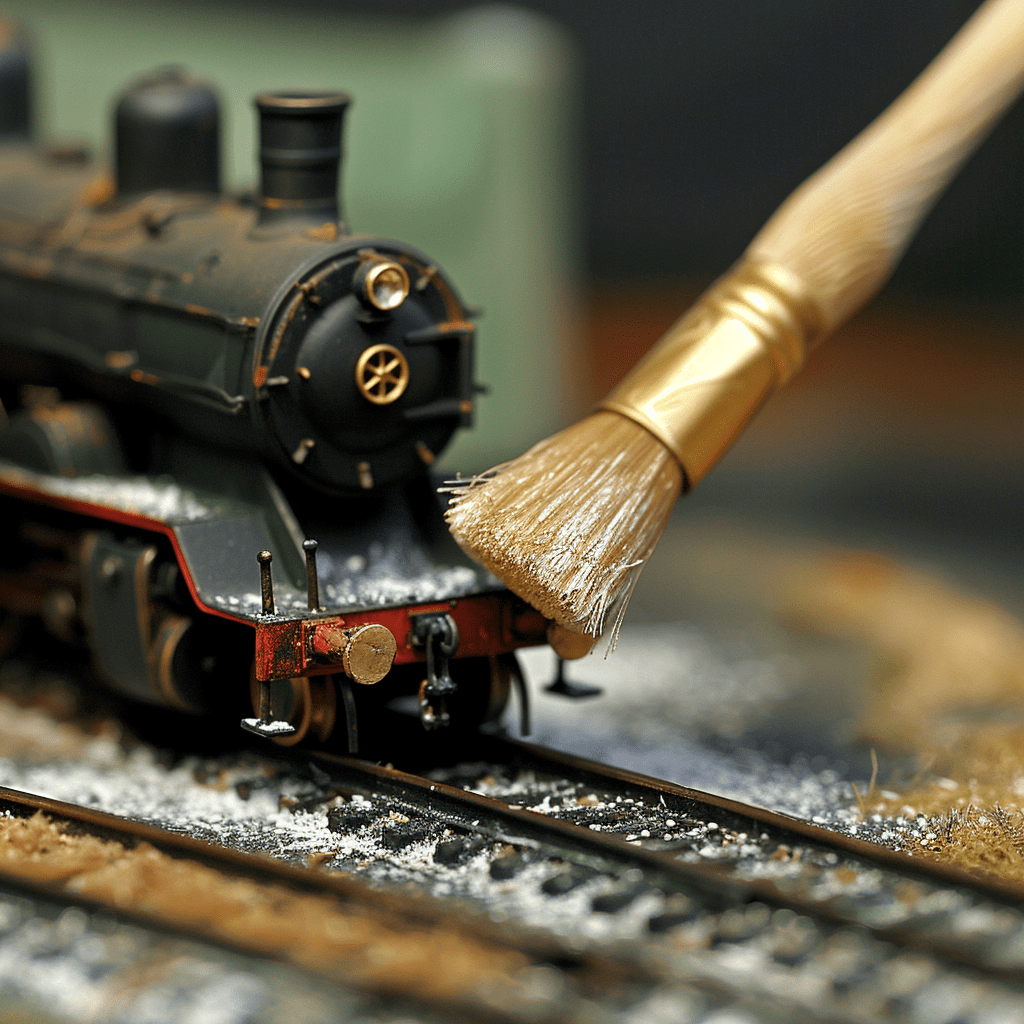

Dust and dirt can accumulate in the nooks and crannies of model trains, affecting their performance. Using a soft brush or compressed air can remove most debris without damaging delicate parts. For more thorough cleaning, disassemble the train and clean each part individually with a soft cloth or small brush.

Neglecting the contacts of your model trains can lead to operational issues. Specialized cleaning products designed for model trains help maintain these critical components. Keeping every part of your model train clean and well-maintained ensures that your trains will continue to bring joy and function smoothly for years to come.

Understanding Model Train Maintenance

Regular maintenance is crucial to keep model trains running smoothly and extend their durability. Knowing the right tools and products will make this task easier.

Importance of Regular Care

Taking care of model trains on a consistent basis can prevent many problems. Regularly checking and cleaning tracks, wheels, and contacts help to ensure the trains operate without interruption. Dirt and dust can accumulate over time, leading to poor performance or complete breakdowns.

Neglecting maintenance can lead to expensive repairs or replacement parts. Simple routines, like wiping down tracks with a lint-free cloth or checking for loose connections, can save time and money.

Tools and Products Overview

Using the right tools and products is essential for proper maintenance. Soft brushes, lint-free cloths, and specialist cleaning solutions are some of the basics. For detailed areas, cotton swabs or small brushes are ideal, as they can reach tight spots without damaging parts.

Certain cleaning agents should be avoided. For example, products like WD-40 can be harmful to plastic and paint. Instead, use products specifically designed for model trains. There are various contact cleaners available that are safe and effective.

A small toolkit including screwdrivers, pliers, and tweezers can make the process easier. Having these on hand helps for quick adjustments and repairs.

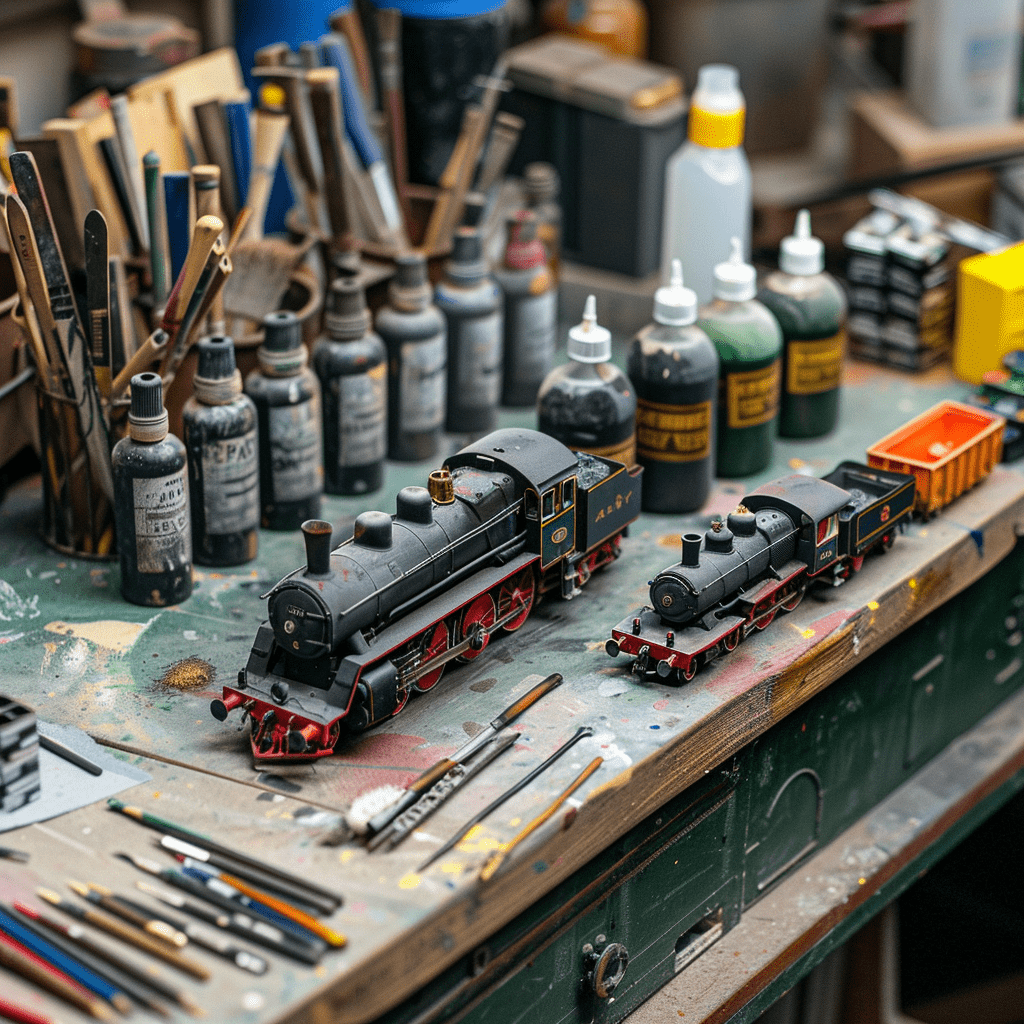

Setting Up the Cleaning Area

Creating an ideal cleaning area for your model trains helps ensure safety and organization. Proper setup and using appropriate tools protect both your space and your model trains.

Creating a Safe Workspace

A safe environment is vital. Choose a clean, well-lit space to minimize the risk of losing small parts. Ensure there's enough room for all the tools and accessories needed. Opt for a sturdy table or bench, which provides a stable surface.

Using an antistatic mat guards against static electricity, which can damage electronic parts. Keep food and drinks away to avoid spills.

Ventilate the area well if using solvents or cleaners. Proper ventilation reduces inhalation risks and improves overall safety.

Organizing Cleaning Tools

Organization helps keep the cleaning process smooth. Gather the necessary tools such as soft cloths, brushes, and tweezers. Store these in labeled containers for easy access.

Use a small tray or a divided box to hold small parts like screws and couplers. This prevents them from getting lost or mixed up.

Keep cleaning products such as isopropyl alcohol and specialized model train cleaners within reach but stored safely to avoid spills. It’s crucial to use the right products to prevent damage to your trains' materials.

Basic Cleaning and Lubrication

Maintaining model trains involves regular cleaning and lubrication. Keeping the wheels and axles clean and properly lubricating moving parts are critical to ensuring smooth operation.

Cleaning the Wheels and Axles

Over time, dirt and grime can build up on the wheels and axles. This can reduce the train's performance and even cause damage. To clean the wheels, use a soft cloth or a special cleaning tool designed for model trains. Moistening the cloth with a bit of rubbing alcohol can help remove stubborn dirt. Avoid using general household cleaners as they may damage the materials.

For the axles, a small brush or a toothbrush can effectively reach and clean around the small spaces. Make sure to clean all contact points, as dirty contacts can lead to poor electrical connectivity. Regularly scheduled cleaning—every few months or more frequently if the trains are used often—will keep your model trains running well.

Lubricating Moving Parts

Lubricating the moving parts of your model trains reduces wear and ensures smooth operation. Use a lubricant specifically made for model trains. Avoid using WD-40 or other multipurpose lubricants as they can damage plastic parts over time. Labelle lubricants are a popular choice and are safe for use on model trains.

Apply a small drop of lubricant to the gears, axles, and other moving parts. It is important not to over-lubricate, as too much grease can attract dirt and grime, which can be counterproductive. Focus on the gearboxes and motor bearings for the best results. Always follow the manufacturer’s instructions for lubrication, as every model train is slightly different.

Track Cleaning Techniques

Keeping your model train tracks clean is essential for smooth operation. This section covers the best ways to clean your tracks, including both manual methods and using specialized cleaning cars.

Manual Cleaning Methods

Regular manual cleaning can keep dirt and grime off the rails. Abrasive blocks, like the Bright Boy, are effective for scrubbing away rust and dirt. Use these blocks gently to avoid scratching the rails.

Vinegar is another popular cleaning agent. Apply it on a cloth to wipe down the tracks. It removes grime and can disinfect. Adding salt helps scrub off stubborn dirt while lemon juice can remove sticky residue.

Alcohol wipes are also useful. They're easy to use and can sterilize the tracks, killing bacteria that may affect performance. Make sure the tracks are dry before running your trains.

Using a Track Cleaning Car

Track cleaning cars can simplify maintenance. These cars come equipped with pads or brushes that clean the tracks as they move. Commercial cleaning cars, such as those made by Märklin or LGB, are popular choices. They often use motorized brushes or abrasive pads to scrub the rails.

Homemade cleaning cars are another option. Create one by attaching a cleaning pad to a regular rail car. Use materials like felt or microfiber for the pad. These cars can be run as part of your regular train operations to maintain clean tracks.

Cleaning cars can run in both directions and can be adjusted for different track gauges. This flexibility makes them a valuable tool for keeping your model railway in top condition.

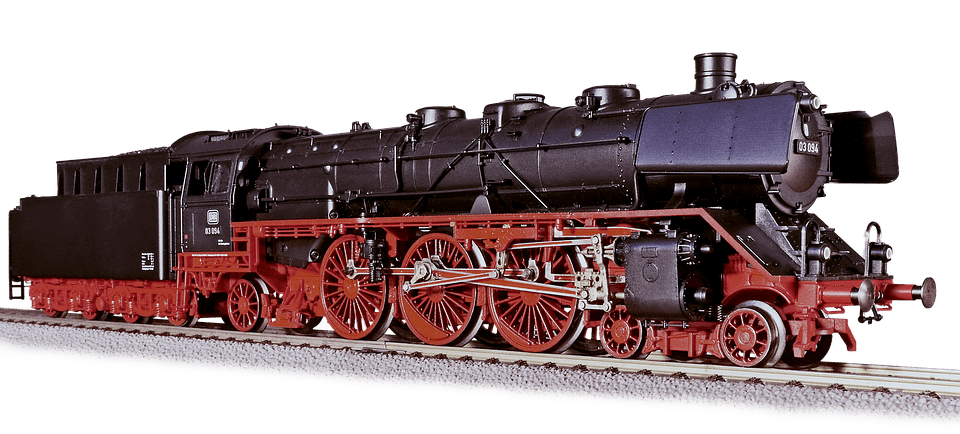

Maintaining Locomotives and Rolling Stock

Proper care of your model trains involves regular servicing and cleaning. This prevents wear and ensures smooth operation.

Servicing the Locomotive

Locomotives need regular maintenance to keep them running efficiently. Start by inspecting the wheels and tracks for dust and debris. Clean the wheels using a soft cloth or specialized wheel cleaner. This helps maintain good electrical contact and smooth running.

Lubrication is key. Apply a tiny amount of oil to the gears and moving parts. Use a lightweight oil specifically designed for model trains. Be careful not to overdo it, as excess oil can attract more dirt. Check the motor and other mechanical parts regularly for wear and replace any worn-out components.

Caring for Rolling Stock

Rolling stock like freight and passenger cars also requires upkeep. Regularly clean the wheels and couplers to prevent dirt buildup, which can cause derailments. Use a small brush or cotton swab to reach tight areas.

Check the axles and wheels for proper alignment. Misaligned wheels can cause operational issues. Also, inspect the hook-and-loop or magnetic couplers for any signs of wear.

Keep rolling stock stored in a dry place to avoid rusting. Protect it from direct sunlight to prevent fading and warping. Regularly dust the exteriors to keep them looking new.

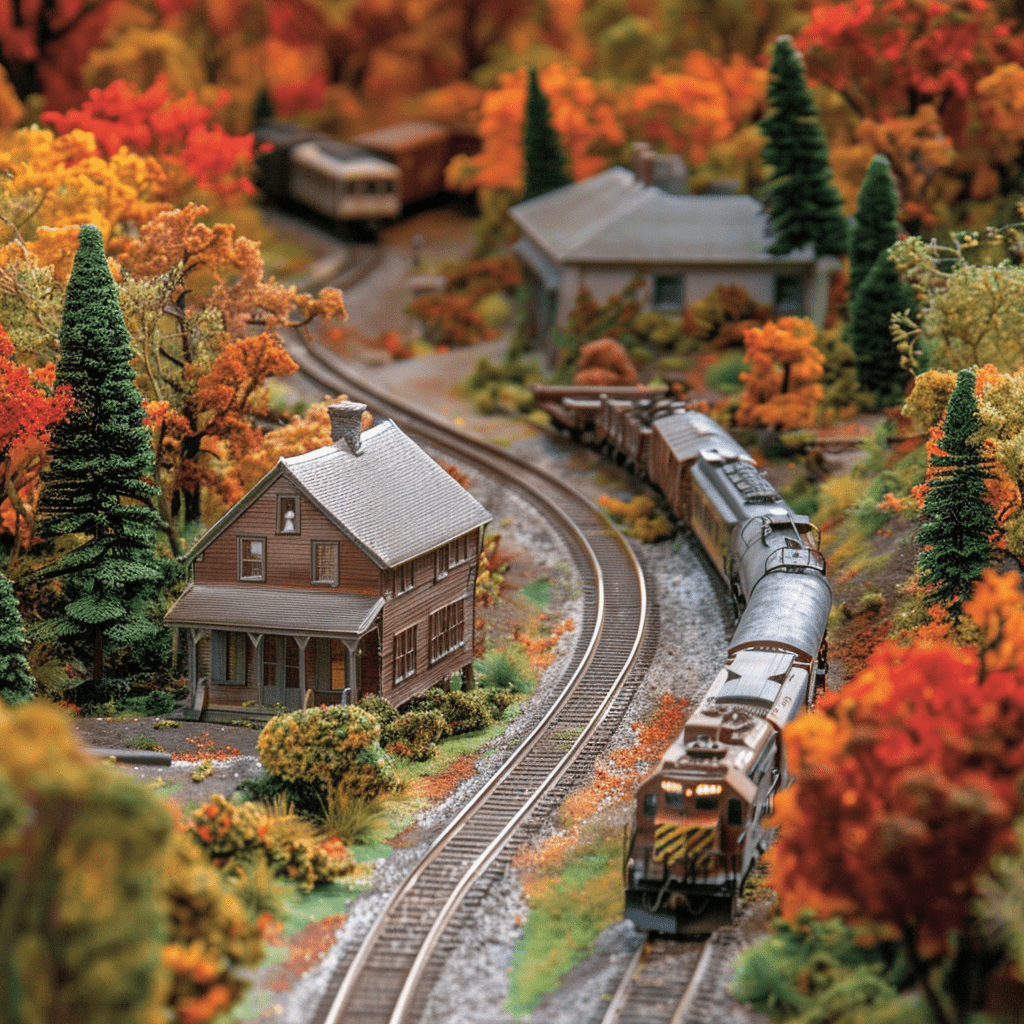

Cleaning Scenery and Structures

Maintaining the cleanliness of both scenery and structures is crucial for a neat and operational model railroad layout. This involves regular dusting of scenic elements and carefully preserving structures.

Dusting Scenic Elements

Dust can quickly accumulate on trees, grass, and other scenic parts. Use a soft duster or a clean, soft brush to gently remove dust from these areas. A vacuum with a brush attachment can also be helpful but use it sparingly to avoid damaging delicate pieces.

For tight corners or areas with lots of details, consider using small tools like cotton swabs or makeup brushes. Lightly dampening the brush can help with stubborn dirt but be careful not to disturb the scenery.

A compressed air canister can blow dust away from hard-to-reach spots. Just use it gently to avoid scattering the scenery materials.

Preserving Structures

Regular maintenance of structures such as buildings, bridges, and other installations is key. A soft cloth or a gentle brush works well for dusting rooftops and walls. Be cautious around fragile details like chimneys, antennas, and vents.

Avoid cleaning products that could harm the material. For more delicate parts, use water and a very mild soap solution. Make sure to dry them thoroughly to prevent water damage.

Glue or repair broken pieces promptly to maintain the appearance of the layout. Regular checks and careful cleaning will make sure your model structures remain in good condition for a long time.

Advanced Techniques for Model Train Care

Taking your model trains to the next level involves careful attention to details and efficiently solving common issues. Here are advanced techniques for keeping your models in top condition.

Detailing with Paint and Decals

Adding paint and decals gives your model trains a realistic look. Use fine-tipped brushes for precise paint application on small areas and intricate details. Airbrushing can provide a smooth and even coat, especially for larger surfaces. Weathering techniques like dry brushing and washes can create a realistic, aged effect.

Decals can add custom logos and signs to your trains. Apply them with tweezers and smooth out air bubbles using a soft cloth or a decal solvent. Seal the decals with a clear coat to protect and set them permanently. This adds durability and enhances the appearance.

Troubleshooting Common Issues

Common issues like derailments and electrical problems can be frustrating. For derailment issues, first check the track alignment to ensure it is level and properly joined. Clean the tracks regularly to remove dust and grime that could cause wheels to slip off.

Electrical problems often stem from poor connections. Inspect the wiring and connectors to make sure they are secure. A multimeter can help in identifying broken circuits or short circuits. Keep the wheels and track contacts clean for efficient power transmission by using a soft cloth or specialized cleaner. Regular maintenance of these components can prevent most issues.

Effective Use of Cleaning Solutions

Proper cleaning solutions keep your model trains in good condition. Choosing the right products and methods helps maintain the quality and longevity of your trains without causing damage.

Choosing the Right Cleaning Agents

Select cleaning agents carefully to avoid harming the materials of your model trains. Avoid harsh chemicals such as WD-40, as they can damage plastic and paint. Instead, use mild soap solutions, distilled water, or specialized model train cleaners.

- Mild Soap Solutions: Safe for most surfaces.

- Distilled Water: Prevents mineral residues.

- Specialized Cleaners: Designed for model trains, ensuring safety and effectiveness.

Test any cleaner on a small, hidden area first. This helps ensure that it won't cause any damage or discoloration.

Preventing Damage from Chemicals

Preventing damage requires understanding how chemicals interact with different materials. Follow these steps:

- Read Labels: Ensure the cleaner is safe for plastics, metals, and paints.

- Use Sparingly: Apply minimal amounts to avoid saturation.

- Ventilation: Clean in well-ventilated areas to avoid inhaling fumes.

Use soft brushes or cotton swabs to apply cleaning solutions gently. Avoid soaking parts, as this can lead to warping or weakening of materials.

Lastly, thoroughly rinse off any residue from cleaning solutions to prevent buildup, which can attract dust and cause further issues.

By adhering to these guidelines, you can effectively clean your model trains without risking damage.

Enhancing the Lifespan of Your Model Trains

Maintaining and upgrading your model trains are essential to keep them running smoothly and extend their longevity. Regular care can prevent damage and ensure optimal performance.

Preventive Maintenance Strategies

Regular cleaning is crucial. Use a soft paintbrush or lint-free cloth to dust the exterior. For hard-to-reach areas, a small brush or cotton swab works well. Avoid harsh chemicals; mild soap and water will do.

Lubrication is another key aspect. Apply a tiny amount of plastic-compatible oil to moving parts like wheels and gears. Be cautious not to over-lubricate as excess oil can attract more dust.

Track cleaning also matters. Dirty tracks can cause poor electrical conductivity. A track cleaning car or a specialized track cleaner can be used to keep them clean.

Also, check for loose screws and connections regularly. Tightening them can prevent long-term issues. Batteries, if used, should be checked and replaced as needed to ensure consistent power.

Replacement and Upgrades

Replacement parts are necessary when components wear out. Keep an eye on wheels, couplers, and connectors, which are most likely to need replacing. Using high-quality parts ensures better durability and performance.

Upgrading components can also enhance the lifespan of your trains. Consider upgrading to more efficient motors or better-quality tracks. Digital Command Control (DCC) systems offer advanced control features and can prolong the operational life of your models.

Modern features such as sound kits and lighting can also make your trains more enjoyable while improving their market value. Making upgrades at the right time can prevent failure and enhance the overall experience.

By following these guidelines, you can ensure that your model trains remain in top condition for years.

Special Considerations for Electronics

When maintaining and cleaning model trains, it's crucial to handle the electronic parts carefully. Paying attention to powered components and cleaning electrical contacts will help ensure smooth operation and longevity.

Handling Powered Components

It's important to disconnect all power sources before handling any powered components. This prevents accidental shorts and damage. Use appropriate tools like plastic tweezers to avoid static discharge, which can harm electronics.

Store each electronic part in anti-static bags. This reduces the risk of damage from static electricity. When cleaning, avoid water or wet cloths. Instead, use a dry, soft brush to remove dust from electronic parts. Always handle these parts by their edges to avoid damaging the circuitry.

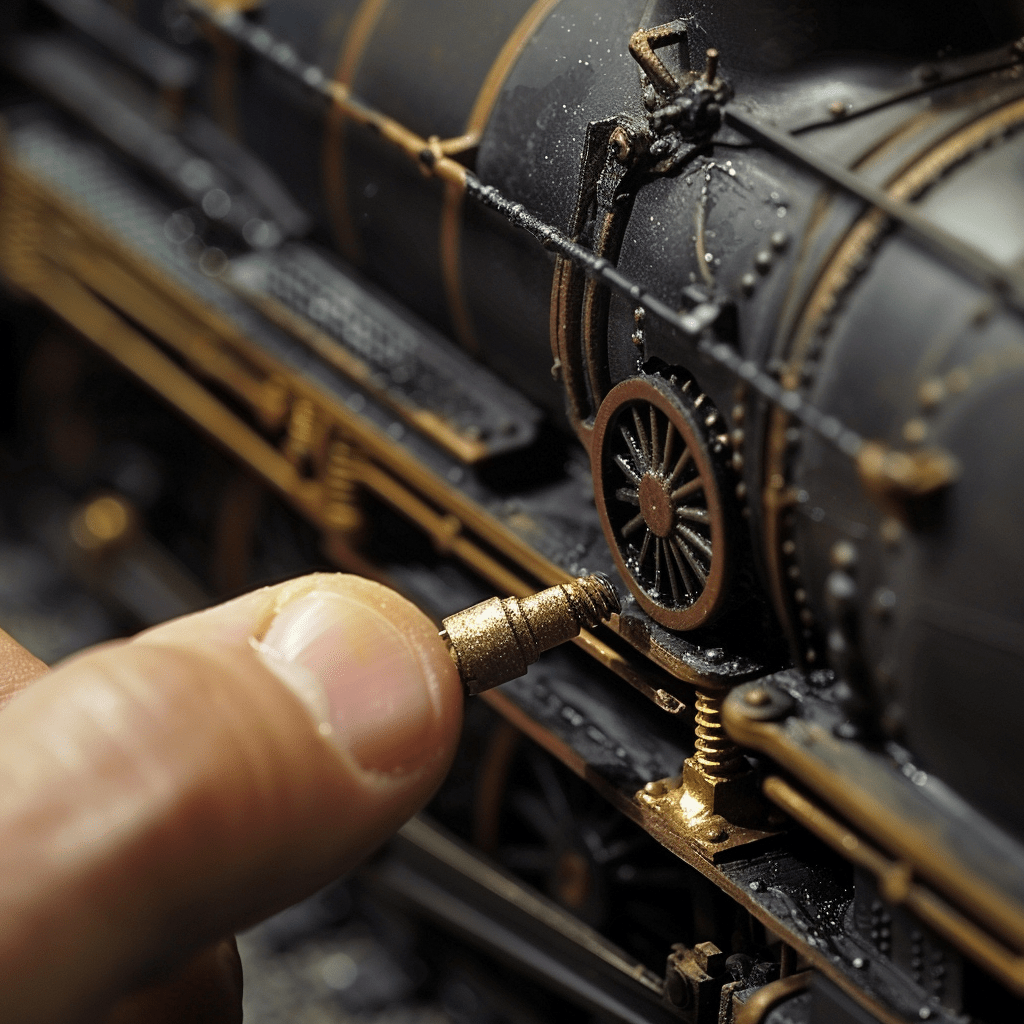

Cleaning Electrical Contacts

Clean electrical contacts ensure reliable power transmission to your model trains. Use a cotton swab dipped in isopropyl alcohol to clean the contacts gently. Alcohol evaporates quickly and doesn’t leave residue.

Avoid abrasive materials as they can damage the contacts. Regularly inspect the electrical pickups and wheels, as dirt buildup can interrupt the electrical flow. Gently polish the contacts with a contact cleaner to maintain optimal performance.

Lastly, ensure all connections are tight but not over-tightened to prevent wear and tear. Regular maintenance of contacts will keep your model trains running smoothly.