Learn About the Nano Train - the World's Smallest Train

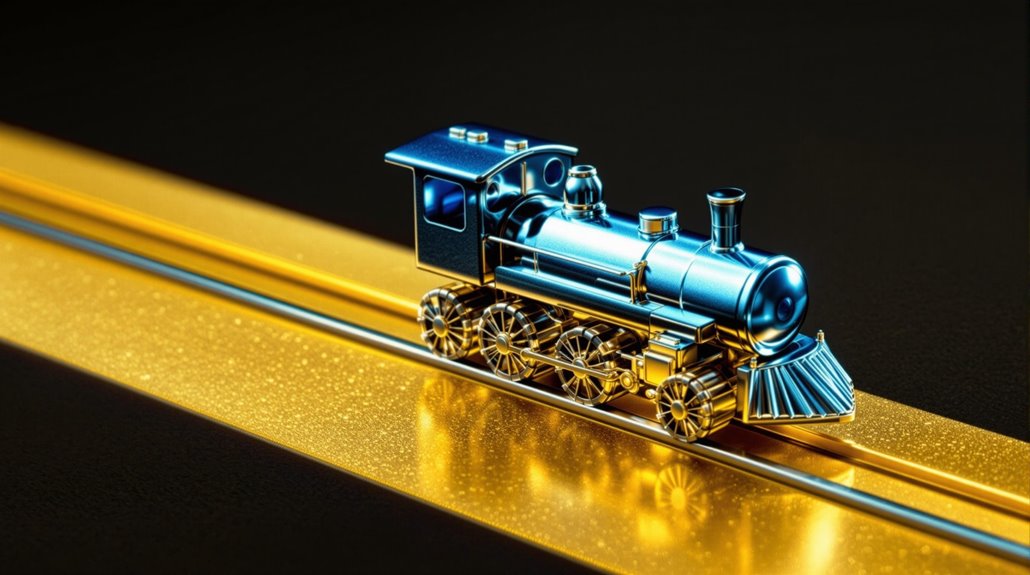

The Nano Train, recognized as the world's smallest train, showcases incredible miniature engineering at just 1/8 inch by 1/4 inch - smaller than your fingernail. You'll find this marvel operating on a 1:220 scale, making it 35,300 times smaller than real-world trains. It features a miniature geared motor within an oval tube system, demonstrating pioneering advances in micro-engineering and modeling techniques. The innovative approaches and technical challenges behind this tiny wonder reveal an fascinating world of ultra-miniature craftsmanship.

The Engineering Marvel Behind the Nano Train

Every once in a while, an invention comes along that challenges our perception of what's possible in engineering. The Nano Train, created by David Smith, does exactly that by pushing the boundaries of microscale engineering to create something extraordinary.

You'd be amazed to learn that this tiny train measures just 1/8 inch by 1/4 inch - smaller than your fingernail. Using advanced nanotechnology and precision craftsmanship, Smith, the designer, engineered a functional miniature train set that operates through a rotating tube mechanism underneath.

What's even more impressive is that this engineering marvel cost only $11 to produce.

This breakthrough demonstrates how microscale engineering can revolutionize various industries, from toy manufacturing to architectural modeling, while maintaining intricate details that collectors and enthusiasts value.

The assembly of such a miniature masterpiece requires precise measurements and careful attention to detail to ensure every component fits perfectly together.

Technical Specifications and Scale Details

To fully appreciate the Nano Train's extraordinary design, you'll need to understand its mind-bending scale. At just 0.2 inches wide, this five-car train is an astonishing 35,300 times smaller than its real-world counterpart. Creator David Smith achieved this astounding feat using basic tools and moldable plastic while working on his larger James River Branch project.

The train operates on a 1:220 scale, making it one of the smallest functional model trains ever built. You'll find the accompanying scenery equally impressive, featuring painstakingly crafted buildings, mountains, and a tunnel - all fashioned from putty. Smith's ongoing project, which has been in development for over two years, promises to transform into an incredible miniature village when completed. Similar to Metal Earth models, this miniature creation demonstrates incredible engineering precision and attention to detail.

Construction Methods and Materials Used

David Smith's innovative approach to building the Nano Train proves that extraordinary achievements don't require expensive materials or complex tools. With just $11 worth of materials, including a knife, moldable plastic, and putty, he crafted an incredibly detailed miniature masterwork.

The construction process involved careful carving of the plastic to create the train's intricate details at a remarkable 1-220 scale. For the James River Branch scenery, Smith used putty to shape colorful buildings, mountains, and even a tunnel. He mounted the entire setup on a two-inch rotating motor head, which cleverly creates the illusion of a moving train.

Through microscale engineering techniques and nanotechnology, Smith achieved precise details in the tiny 1/8 by 1/4 inch train, demonstrating that imagination can metamorphose simple materials into extraordinary creations. Unlike traditional model kits that often use photo-etched metal parts for intricate details, Smith relied solely on basic materials to achieve his remarkable results.

The James River Branch Project Vision

While most model train enthusiasts work on conventional scales, the James River Branch project aims to exceed the limits of miniaturization to extraordinary levels. David Smith's ambitious vision includes creating a complete miniature village at 1:220 scale, with the centerpiece being the world's smallest working train set.

You'll find this noteworthy nano-scale train, measuring just 1/8 by 1/4 inch, nestled inside a hobby shop within the larger village layout. Like many innovative model railroad projects in New Jersey and across America, Smith's dedication to detail and engineering excellence drives this two-year-plus effort.

Though the completion date remains unannounced, Smith's promise of a "quite incredible" finished product has generated buzz among enthusiasts who eagerly await this pioneering achievement in miniature modeling.

Overcoming Miniaturization Challenges

Creating the world's smallest working train set presented several complex engineering challenges that required innovative solutions. When you miniaturize a geared mechanism to this scale, friction becomes a major obstacle. The breakthrough came by using an oval tube attached to a tiny geared motor, with carefully cut teeth along the tube's edge to create the train cars.

Building the layout required exceptional precision, using ultra-thin styrene and Squadron putty for the terrain details. You'll find that lighting posed another significant hurdle, as traditional LEDs and fiber optics were too large for the nano-scale buildings.

Even documenting the project proved challenging - capturing video footage of such tiny movements required 400% magnification in post-production to make the details visible to viewers.

Visual Design and Landscape Elements

Despite its tiny size, the nano train set's scene packs impressive visual detail into a two-inch diameter display. You'll find the train circling atop a motorized base that creates fluid movement around the meticulously crafted landscape.

The scene is part of the ambitious James River Branch project, built at an incredibly small 1-220 scale. You'll uncover colorful buildings nestled among carefully shaped mountains, with a detailed tunnel adding depth to the miniature world. The creator's dedication shows in every element, from the putty-crafted structures to the perfectly proportioned terrain.

As this two-year project continues to evolve, you're witnessing just a portion of what'll become an expansive miniature village. The attention to detail in this tiny display hints at the exceptional scope of the complete James River Branch.

Impact on Model Railroad Innovation

As miniaturization pushes the boundaries of model railroading, the nano train project has sparked a wave of innovation throughout the industry. David Smith's creation of the World's Smallest Train has opened new possibilities for collectors and enthusiasts alike, demonstrating that functional model trains can exist at previously unimaginable scales.

You'll find the nano train's impact extending across multiple areas of model railroading:

- Advanced microscale engineering techniques that'll revolutionize how manufacturers generate ultra-detailed components

- New opportunities for exclusive collectibles that push the limits of precision craftsmanship

- Development of specialized tools and equipment for working with microscale layouts

- Integration of innovative motorization methods, like the rotating tube mechanism, that could alter future model train designs

These breakthroughs aren't just technological achievements - they're reshaping what's possible in the model railroad hobby.

David Smith's Journey and Expertise

Behind every pioneering innovation stands a passionate creator, and David Smith's odyssey in model railroading spans over five decades. Since 1965, he's specialized in crafting smaller-scale models, leading to his groundbreaking nano train project.

Smith's dedication shines through his meticulous attention to detail, evident in his latest creation: a five-car train running through a scenic layout measuring just 0.125 x 0.2 inches.

You'll appreciate how he tackled significant technical obstacles, from friction issues in the geared mechanism to visibility challenges that required 400% video zoom. When conventional solutions like LEDs proved too large for illuminating his 1:35,200 scale creation, Smith innovated by developing an oval tube system with a miniature geared motor, demonstrating his problem-solving prowess in ultra-miniature modeling.