History of Model Car Building

The history of model car building traces back to the late 19th century, transforming from simple wooden toys to intricate replicas. In the early 1900s, manufacturers used materials like tin and lead, with die-cast techniques emerging in the 1930s. The 1950s and 1960s marked the golden age, with brands like Dinky Toys and Matchbox popularizing die-cast models. Plastic kits revolutionized the hobby in the 1950s, allowing for greater customization. Over time, technological advancements have improved precision and detail, while collecting culture has grown notably. From promotional models to limited editions, the world of model cars continues to fascinate enthusiasts with its rich history and craftsmanship.

Origins of Miniature Automobiles

The humble beginnings of miniature automobiles can be traced back to the late 19th century. You'll find that these early model cars were simple metal and wooden playthings designed for children's enjoyment.

As the automotive industry grew, so did the desire for more realistic miniature representations.

A significant milestone in the evolution of model cars came in 1897 when the Rossignol brand introduced the first steam-powered miniature automobile. This innovation demonstrated the potential for creating scale models with realistic locomotion, facilitating the development of more sophisticated replicas.

Charles Rotel's contributions to miniature car development were indispensable, as his stapling assembly innovations allowed for more detailed and accurate reproductions. As the 20th century progressed, you'd notice manufacturers producing increasingly intricate and true-to-life miniature car models, catering to a growing collector market.

Early Materials and Techniques

Delving into the early materials and techniques of model car building, you'll find a fascinating evolution of craftsmanship. In the late 19th and early 20th centuries, model cars were primarily made of tin, lead, and plaster. These materials allowed for basic representations of automobiles but lacked the detail and durability we see today.

As manufacturing techniques improved in the 1930s and 1940s, diecast metal model cars emerged. Zamak, an alloy of zinc, aluminum, magnesium, and copper, became a popular choice for producing these miniature vehicles. Pressed steel was another common material used during this period, offering a sturdier alternative to earlier materials.

The 1950s and 1960s saw a significant shift in model car production with the introduction of plastic and resin casting processes. These new techniques allowed for more intricate designs and affordable production methods.

Here are five key points to remember about early model car materials and techniques:

- Tin, lead, and plaster were used in the earliest model cars

- Diecast metal techniques emerged in the 1930s and 1940s

- Zamak alloy became popular for diecast metal models

- Pressed steel was a common early 20th-century material

- Plastic and resin casting revolutionized production in the 1950s and 1960s

Rise of Die-Cast Models

During the 1950s, die-cast metal models revolutionized the model car industry. You'd witness the emergence of iconic brands like Dinky Toys, Corgi, and Matchbox, which quickly gained popularity among enthusiasts. These manufacturers began producing highly detailed scale replicas that would forever change the state of model car collecting.

Dinky Toys played a vital role in establishing the 1/43 scale as a standard for detailed diecast miniatures. This scale, along with others, became one of the most popular scales for collectors. The new die-cast models featured an unparalleled level of detail, including moving parts and realistic paint schemes. You'd be amazed by the intricate craftsmanship that went into these miniature automobiles.

As the quality and attention to detail improved, model cars evolved from simple toys to prized collectibles. The 1950s and 1960s saw a significant growth in the hobby of collecting model cars. Enthusiasts were drawn to the high-quality diecast models, appreciating the craftsmanship and realism they offered. This shift in perception raised model cars to a new status, attracting a wider range of collectors and cementing their place in popular culture.

The Golden Age: 1950s-1960s

Building upon the foundation laid by die-cast models, the 1950s and 1960s ushered in the golden age of model car building. This era saw the emergence of iconic brands like Dinky Toys, Corgi, and Matchbox, which revolutionized the industry. Dinky Toys played a crucial role in establishing the 1/43 scale as the standard for model cars, setting a benchmark for detail and accuracy.

During this period, you'd find model cars crafted from die-cast metal, featuring exceptional levels of detail. The availability of affordable, high-quality models from various manufacturers fueled the rapid expansion of the model car collecting market. As a result, collecting became a popular hobby, with enthusiasts seeking out rare models from this iconic era.

The golden age laid the groundwork for the continued evolution of model car building, leaving a lasting impact on the hobby. Today, you can still experience the magic of this era by:

- Hunting for vintage Dinky Toys, Corgi, and Matchbox models

- Appreciating the intricate details of 1/43 scale die-cast metal cars

- Joining model car collecting communities to share your passion

- Attending model car shows and exhibitions

- Restoring and preserving rare models from the 1950s and 1960s

Scale Sizes and Precision

From miniature replicas to large-scale models, the world of model car building offers a diverse range of scale sizes to suit every enthusiast's preference. You'll find scale models ranging from tiny 1:120 versions to impressive 1:10 replicas, with popular sizes including 1:43, 1:24, and 1:18.

When you're exploring the world of model cars, you'll notice that larger scales like 1:12 and 1:10 provide more intricate details and features. On the other hand, smaller scales such as 1:64 prioritize affordability over precision. European car manufacturers typically focus on high-precision 1:43 and 1:18 scale models, while the US market has traditionally favored more cost-effective 1:25 and 1:24 scales.

The choice of scale is influenced by various factors, including manufacturing costs, target market, and desired level of detail. Advancements in technology, such as 3D printing and computer-aided design, have revolutionized the manufacturing process. These innovations allow model car manufacturers to produce increasingly detailed models across various scales, pushing the boundaries of precision and realism in the hobby.

European vs. American Models

Two distinct approaches to model car building emerged on opposite sides of the Atlantic. European manufacturers like Dinky, Corgi, and Solido focused on smaller 1:43 scale models with intricate details, while American companies like AMT and Revell produced larger 1:25 scale plastic model kits.

European models were often made of die-cast metal, featuring complex elements like opening parts and detailed interiors. In contrast, American models were typically injection-molded plastic, designed for assembly and simpler in construction. The European market for model cars developed earlier, with Dinky Toys establishing itself in the 1930s, while the American hobby gained momentum in the 1950s and 1960s.

Labor and material costs influenced these different approaches, resulting in more expensive and intricate European models compared to their American counterparts. As you investigate the world of model cars, you'll notice these distinct characteristics:

- European models: Smaller scale, higher detail

- American models: Larger scale, assembly required

- European preference for die-cast metal

- American focus on plastic models

- Earlier development of the European market

These differences shaped the model car industry, offering enthusiasts a diverse range of options to collect and construct.

Promotional and Licensed Models

While European and American manufacturers developed distinct approaches to model cars, another significant trend emerged in the industry: promotional and licensed models. This trend revolutionized the way car companies marketed their brands and interacted with consumers.

Promotional model cars became a popular advertising tool, with manufacturers producing toy car replicas featuring logos and brand inscriptions. Often crafted as banks, these models served both promotional purposes and as collectibles. The promotional model car hobby reached its peak in the 1950s and 1960s, with AMT leading the charge by introducing 1/25 friction and coaster promo models in 1948.

As the demand for these miniature car replicas grew, model companies began competing to accurately reproduce vehicle details. This competition led to increasingly intricate designs, with plastic promo models duplicating even the smallest features of real cars. Car companies recognized the potential of these toys and licensed their designs to multiple model manufacturers. This strategy allowed them to reach a wider audience, as promotional models were marketed and sold in retail stores, alluring both children and adult collectors alike.

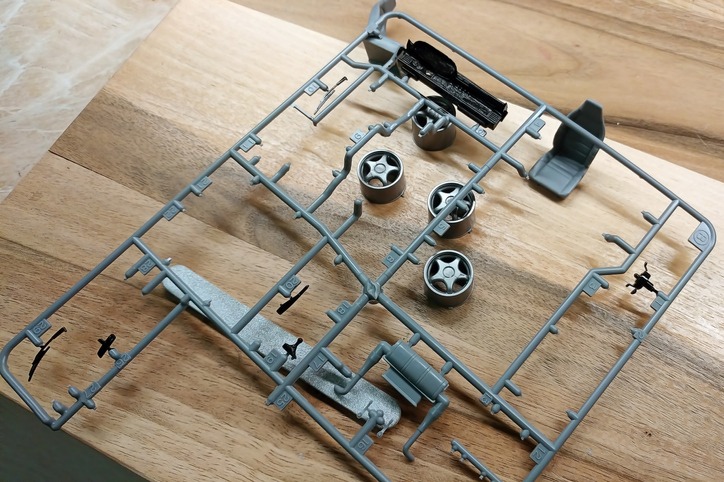

Plastic Kits and Customization

During the 1950s, the model car hobby underwent a significant alteration with the introduction of plastic kits. Companies like Revell and Aurora pioneered injection molding techniques, making plastic model cars more affordable and versatile. This innovation allowed hobbyists to construct and customize miniature cars with greater ease and detail.

As the 1960s rolled in, you'd find an explosion of options in the plastic model car world. Brands like Tamiya, Hasegawa, and Italeri pushed the boundaries of detail and accuracy in their car models. The hobby evolved, offering you more opportunities for customization and creativity in building model cars.

Improved molding techniques for better detail

Greater accuracy in scale and proportions

More diverse selection of car models

Enhanced customization options

User-friendly assembly processes

The plastic model car industry continued to grow through the late 20th century, with Chinese manufacturers dominating production. Today, advancements in 3D printing and CAD have revolutionized the hobby, making it easier than ever for you to create highly detailed and personalized model cars. Whether you're a beginner or an experienced modeler, the world of plastic model car building offers endless possibilities for creativity and enjoyment.

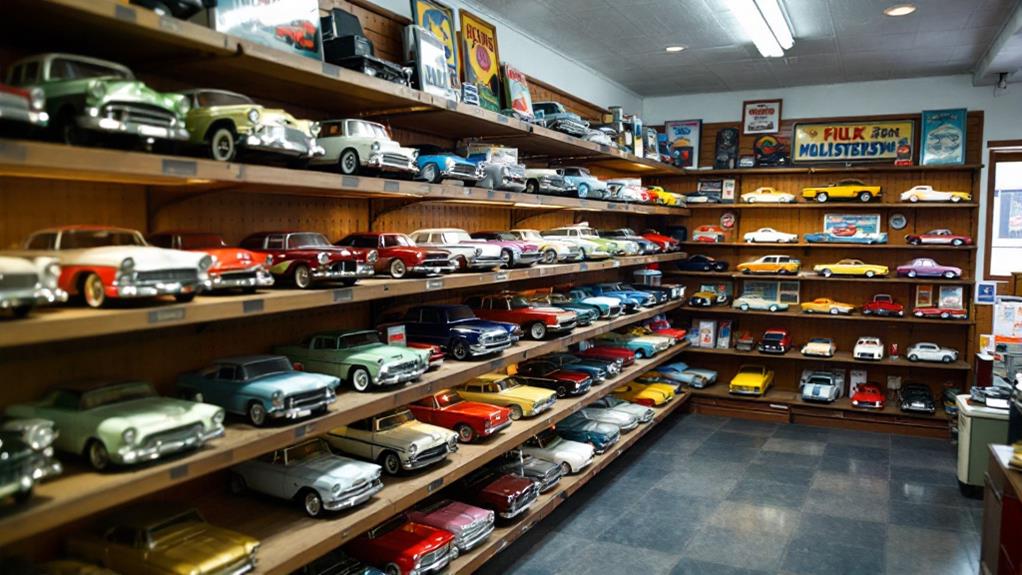

Collecting Culture and Trends

As plastic model car building flourished, a new trend emerged alongside it: collecting. In the 1960s and 1970s, collecting model cars became a popular adult hobby, driven by a desire for rare and discontinued models. This shift from wooden model kits to collecting ready-made models produced a surge in demand for sought-after pieces.

Manufacturers took notice and started producing exclusive, limited edition models specifically for adult collectors. From classic Ford Mustang replicas to rare white metal castings, collectors and enthusiasts keenly sought out these unique pieces.

You'll find that specialized model car shops and dealers began catering to this growing market, facilitating the rise in prices for coveted models.

The appeal of model car collecting has been sustained by nostalgia and a connection to automotive history. You'll uncover that technological advancements, such as 3D printing, have opened up new avenues for obtaining unique and customized designs. As the hobby continues to evolve, you'll see that the passion for collecting model cars remains strong, with enthusiasts constantly searching for that perfect addition to their collection.

Technology's Impact on Production

Over the past few decades, technology has dramatically reshaped the model car production panorama. Since World War II, the model car industry has evolved from simple, mass-produced toys to highly detailed collectibles. In the technological era, you'll find that advancements have revolutionized how these popular miniatures are made.

Computer-aided design (CAD) software has transformed the car industry, allowing designers to create intricate digital prototypes before physical production. This technology, combined with improved plastic injection molding and 3D printing, has enabled manufacturers to produce kits with unparalleled levels of detail and accuracy.

The impact of technology on model car production is evident in:

- Enhanced realism through multi-material molding and hydro-dipping

- Precision tooling and CNC machining for consistent, high-quality parts

- 3D printing empowering hobbyists to create custom accessories

- Improved affordability due to efficient manufacturing processes

- Digital design tools enabling rapid prototyping and iteration

These advancements haven't only improved the quality of model cars but also expanded creative possibilities for enthusiasts. Whether you're in the United States or elsewhere, you can now enjoy model cars with exceptional detail and realism, thanks to these technological innovations.